Lithium-Ion Batteries

Measurements and characterizations to understand lifetime dynamics

- Recipe development and supply chain control: Inspection of intact samples for effective supplier control, revealing changes in recipe or cost savings that may affect battery’s performance or longevity

- Safety and quality inspection: Identification of debris, particle formation, burrs at the electrical contact or damage to the polymer separator

- Lifetime and aging effect: Longitudinal studies of aging effects

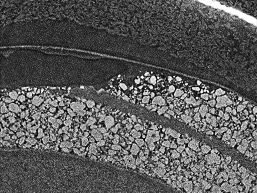

Small pouch cell (80 kV) – in situ microstructure, aging effect at cathode grain level, separator layer.

(Source: https://www.zeiss.com/microscopy/int/products/x-ray-microscopy/zeiss-xradia-610-and-620-versa.html)

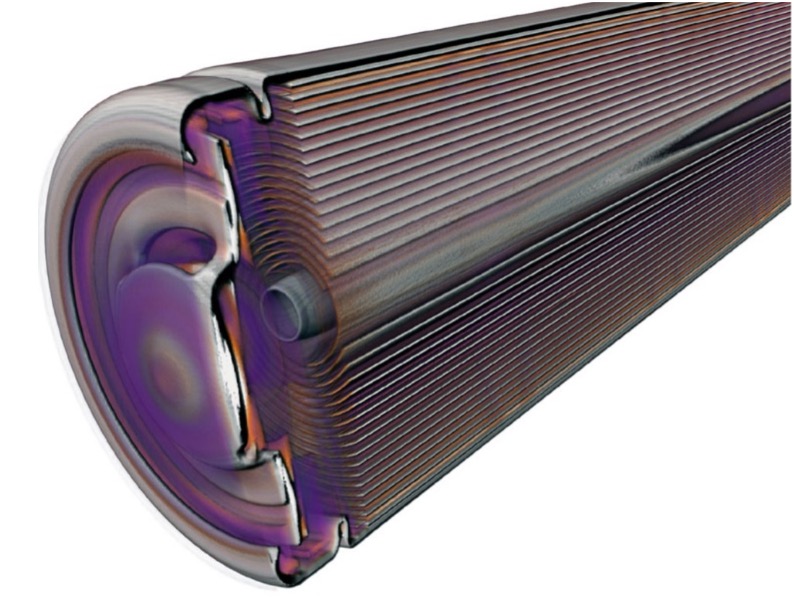

An 18650 Li-ion battery measured with ZEISS Xradia 620 Versa.

(Source: "An overview of 3D X-ray Microscopy", MICROSCOPY AND ANALYSIS, Essential Knowledge Briefings,Second Edition 2020, Zeiss.

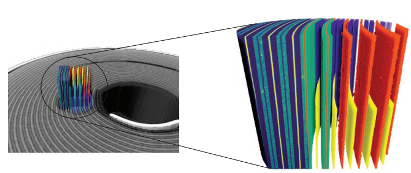

Intact cylinder cell (160 kV) – welding burrs, metallic inclusions, folds and kinks in conductive layers.

(Source: https://www.zeiss.com/microscopy/int/products/x-ray-microscopy/zeiss-xradia-610-and-620-versa.html)

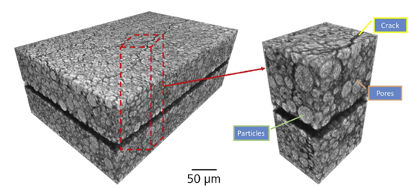

3D volume rendering of the positive electrode layer, showing the particles, pores, and cracks/defects throughout the specimen thickness.

(Source: J. Gelb, D. P. Finegan and D. J. Brett, "Multi-scale 3D investigations of a commercial 18650 Li-ion battery with correlative electron- and X-ray microscopy," Journal of Power Sources, vol. 357, pp. 77-86, 2017).