Additive Manufacturing

Defect detention and characterization within additive manufactured parts as a key to efficient and effective process development

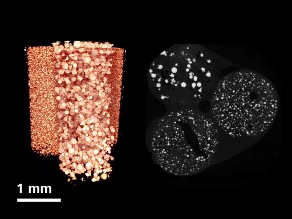

- Detailed shape, size, and volume distribution analysis of particles in Additive Manufacturing (AM) powder bed to determine proper process parameters

- High-resolution, non-destructive imaging for microstructural analysis of AM parts

- 3D imaging for comparison with the nominal CAD representation

- Detection of unmelted particles, high-Z inclusions, and voids

- Surface roughness analysis of inner structures that cannot be accessed by other methods.

Imaging of different A205 AM powder qualities at 3.9 µm voxel resolution.

(Source: https://www.zeiss.com/microscopy/int/products/x-ray-microscopy/zeiss-xradia-610-and-620-versa.html)

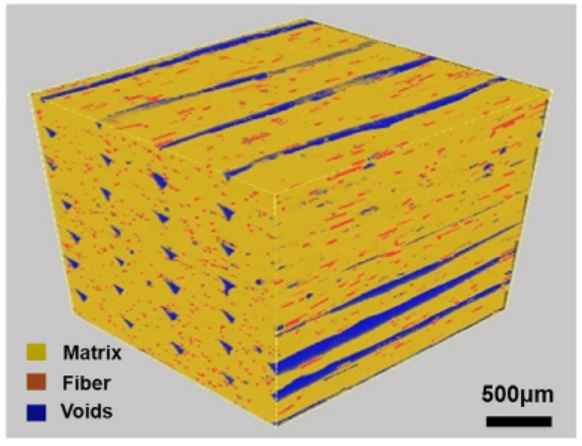

3D microtomo-graphic image of 3D-printed basalt fiber-reinforced PLA composite where matrix, fibers and voids can be clearly distinguished.

(Source: "Analytical study on the 3D-printed structure and mechanical properties of basalt fiber-reinforced PLA composites using X-ray microscopy, Siwon Yu et al, Composites Science and Technology Volume 175, 3 May 2019, Pages 18-27

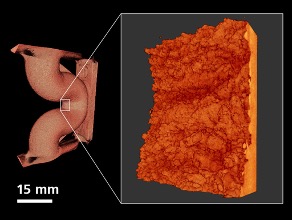

Surface roughness evaluation of an AM printed duct (Ti-6Al-4V); high resolution scan acquired at ~1.7 mm voxel over a ~3.4 mm area